Views: 222 Author: Ella Publish Time: 2025-06-04 Origin: Site

Content Menu

● Understanding OEM Knife Sharpener Manufacturing

>> What is an OEM Knife Sharpener?

>> How Does OEM Manufacturing Work?

● Why Choose Chinese OEM Knife Sharpener Manufacturers?

>> Advantages of Chinese OEM Factories like INSIGHT Kitchenknife

● Key Factors to Consider When Choosing an OEM Knife Sharpener Factory

>> 1. Reputation and Experience

>> 2. Technical Expertise and Manufacturing Capabilities

>> 3. Quality Assurance and Certifications

>> 4. Customization and OEM Services

>> 5. Cost Efficiency and Production Capacity

>> 6. After-Sales Support and Warranty

● Types of Knife Sharpeners Offered by OEM Factories

● Innovations in Knife Sharpener Manufacturing

● How to Evaluate an OEM Knife Sharpener Factory

>> Step 2: Factory Visit or Virtual Tour

>> Step 3: Review Quality Control Procedures

>> Step 4: Assess Communication and Responsiveness

>> Step 5: Negotiate Terms and Agreements

● Proper Use and Maintenance of OEM Knife Sharpeners

● Frequently Asked Questions (FAQs)

>> 1. What types of knife sharpeners can OEM factories produce?

>> 2. How can I ensure the quality of knife sharpeners from an OEM factory?

>> 3. Can OEM factories customize knife sharpeners to my brand's specifications?

>> 4. Are electric knife sharpeners from OEM factories safe to use?

>> 5. What are the benefits of sourcing knife sharpeners from Chinese OEM manufacturers?

Maintaining sharp knives is essential for both professional chefs and home cooks. A high-quality knife sharpener ensures that blades remain effective, safe, and long-lasting. For businesses looking to develop their own branded knife sharpeners, partnering with the right OEM (Original Equipment Manufacturer) factory is crucial. This comprehensive guide will walk you through the process of selecting the perfect OEM knife sharpener factory, covering everything from understanding OEM manufacturing to evaluating factories, and ensuring product quality. Insights from leading manufacturers such as INSIGHT Kitchenknife enrich this discussion, illustrating best practices and industry standards.

An OEM knife sharpener is a product manufactured by a factory that produces sharpeners or their components based on another company's design and specifications. The finished sharpeners are then branded and sold under the purchasing company's name. This model allows brands to leverage the manufacturing expertise and facilities of specialized factories without investing in production infrastructure themselves.

The OEM manufacturing process typically involves several stages:

- Understanding Client Needs: The OEM factory collaborates closely with the client to understand product requirements, target markets, and design preferences.

- Design and Prototyping: The factory develops detailed designs and prototypes to ensure the sharpener meets functional and aesthetic expectations.

- Material Selection: High-quality materials like diamond-coated wheels, ceramic rods, or high-carbon steel are sourced to guarantee durability and sharpening efficiency.

- Production and Quality Control: Mass production is carried out with rigorous quality checks to ensure consistency and performance.

This process allows brands to focus on marketing and sales while relying on the OEM factory's expertise to deliver superior products.

China is a global leader in manufacturing kitchenware, including knife sharpeners. Many Chinese manufacturers, such as Yangjiang Insight Hardware Products Co., Ltd operating under the brand INSIGHT Kitchenknife, offer extensive OEM and ODM services that cater to diverse market needs.

- Comprehensive Product Range: From manual diamond sharpeners and whetstones to electric multi-stage sharpeners, Chinese factories provide a wide variety of sharpening tools suitable for all kitchen needs.

- Advanced Materials and Technology: INSIGHT Kitchenknife utilizes diamond-coated wheels and ceramic rods, ensuring fast, durable, and efficient sharpening.

- Customization Capabilities: They offer tailored designs, packaging, and branding options to help businesses create unique products that stand out globally.

- Quality Assurance: Factories maintain certifications such as ISO9001 and CE, implement strict quality control, and provide product samples for evaluation.

- Competitive Pricing and Production Capacity: Thanks to economies of scale and advanced manufacturing, Chinese OEM factories deliver cost-effective solutions without compromising quality.

- Ergonomic and User-Friendly Designs: Products feature comfortable handles, non-slip bases, and compact sizes, enhancing safety and ease of use.

INSIGHT Kitchenknife exemplifies these strengths, making it a preferred partner for companies seeking reliable OEM knife sharpener manufacturing[1].

Select a factory with a proven track record in manufacturing knife sharpeners. INSIGHT Kitchenknife, for example, is recognized for its commitment to quality and innovation in both China and Korea, operating large-scale facilities with advanced production lines[1][4].

Ensure the factory has the machinery and know-how to produce the sharpener type you require — manual, electric, multi-function, or specialty sharpeners. INSIGHT Kitchenknife's use of diamond-coated wheels and ceramic rods reflects cutting-edge sharpening technology[1].

Factories should have certifications such as ISO 9001 and CE to guarantee adherence to international standards. INSIGHT Kitchenknife maintains these certifications and conducts rigorous quality checks[1].

A factory offering OEM and ODM services can tailor products to your specifications, including design, packaging, and branding. INSIGHT Kitchenknife supports laser engraving, silk screen printing, and etching for logos, enhancing brand identity[1][3].

Evaluate pricing models and production capabilities to ensure your orders can be fulfilled on time and within budget. INSIGHT Kitchenknife's large-scale manufacturing and logistics infrastructure support timely delivery worldwide[1].

Reliable after-sales service, warranty, and technical support are essential for maintaining customer satisfaction and brand reputation.

OEM factories manufacture a wide range of knife sharpeners, including:

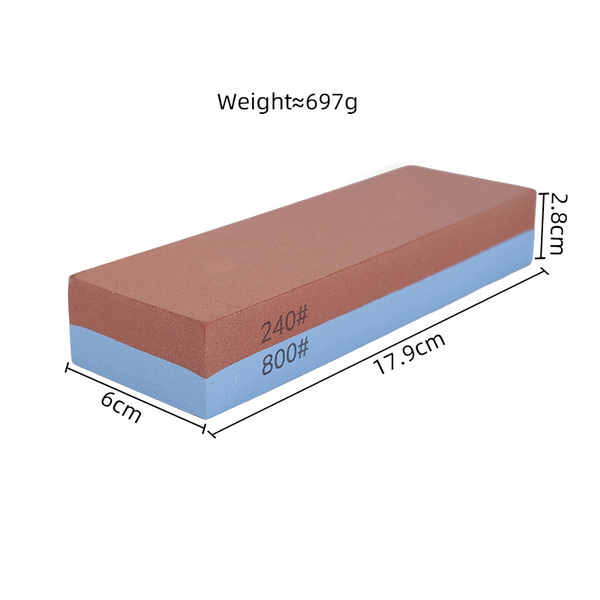

- Manual Sharpeners: Whetstones, diamond rods, ceramic rods, and pull-through sharpeners ideal for precise control.

- Electric Sharpeners: Motorized devices with multiple abrasive stages for quick and consistent sharpening.

- Multi-Function Sharpeners: Tools designed to sharpen knives, scissors, serrated blades, and other cutting instruments.

- Specialty Sharpeners: Designed for ceramic knives or industrial cutting tools.

INSIGHT Kitchenknife produces various models, including stainless steel knife sharpener rollers featuring diamond and ceramic grinding discs, magnetic fixation for stability, and multiple grinding angles (15°, 18°, 20°, 22°), suitable for a wide range of knives[3].

OEM factories like INSIGHT Kitchenknife invest heavily in research and development to improve sharpening technology. Innovations include:

- Diamond-Coated Wheels and Rods: For enhanced durability and faster sharpening.

- Ergonomic Handles and Non-Slip Bases: To improve safety and user comfort.

- Compact and Portable Designs: Facilitating easy storage and travel.

- Water- and Oil-Free Sharpening: Offering a cleaner and more convenient sharpening process.

- Multi-Stage Sharpening Systems: Combining coarse grinding and fine honing for superior edge restoration.

- Magnetic Fixation Designs: Increasing stability during sharpening, as seen in INSIGHT's stainless steel sharpener rollers[1][3].

Ask for product samples to assess build quality, sharpening performance, and material durability. INSIGHT Kitchenknife provides samples within 5-7 days, allowing clients to test before committing[3].

If possible, visit the factory or request a virtual tour to inspect manufacturing processes, equipment, and working conditions.

Inquire about inspection protocols, testing methods, and defect rates. INSIGHT Kitchenknife implements strict quality control aligned with international standards[1].

Choose a factory with clear, prompt communication to ensure smooth collaboration.

Discuss pricing, minimum order quantities (MOQs), lead times, intellectual property protection, and warranty terms before signing contracts.

To maximize the lifespan and effectiveness of your knife sharpeners:

- Use the correct sharpening slot or surface for your knife's dullness level.

- Maintain recommended sharpening angles (usually 15°-20°).

- Clean sharpening stones and rods regularly to remove metal debris.

- Avoid oils unless specified.

- Store whetstones properly, either dry or soaked, as instructed.

INSIGHT Kitchenknife provides detailed usage instructions with their products to ensure safe and effective sharpening[1].

Selecting the right OEM knife sharpener factory is a strategic decision that impacts product quality, brand reputation, and customer satisfaction. Chinese manufacturers like INSIGHT Kitchenknife exemplify excellence in this field, offering advanced manufacturing capabilities, customization, competitive pricing, and stringent quality control. By carefully evaluating factories based on experience, technical expertise, certifications, and after-sales support, brands can secure reliable partners to deliver superior knife sharpeners that meet global market demands. Proper collaboration and clear communication ensure products stand out for their performance, durability, and user-friendly design, fostering long-term business success.

OEM factories manufacture manual sharpeners (whetstones, diamond rods), electric sharpeners with multi-stage processes, multi-function sharpeners, and specialty sharpeners for ceramic knives and other tools[1][3].

Request product samples, verify certifications like ISO9001 and CE, review quality control procedures, and check client testimonials before finalizing a partnership[1].

Yes, many OEM factories, including INSIGHT Kitchenknife, offer OEM and ODM services allowing customization of design, packaging, logos, and features[1][3].

Yes, reputable manufacturers design electric sharpeners with safety features such as non-slip bases and ergonomic handles. Proper use according to instructions ensures safe operation[1].

Benefits include competitive pricing, wide product variety, advanced technology, customization options, reliable supply chains, and adherence to international quality standards[1].