Views: 222 Author: Ella Publish Time: 2025-05-23 Origin: Site

Content Menu

● The Korean Knife Sharpening Industry: An Overview

● Leading Knife Sharpener Manufacturers in Korea

>> 1. INSIGHT Kitchen Knife Factory

>> 2. Master Shin (Anseong Daejanggan)

>> 3. Everwealth Knife Factory

>> 4. LeeKnives

>> 5. Holy Industries Co., Ltd.

● Unique Characteristics of Korean Knife Sharpeners

● How Korean Knife Sharpeners Work

● Modern Innovations in Korean Knife Sharpeners

● The Role of Tradition in Korean Sharpening Tools

● Choosing the Right Korean Knife Sharpener for Your Needs

● Maintenance Tips for Korean Knife Sharpeners

● FAQ

>> 1. What makes Korean knife sharpeners different from Japanese or Western sharpeners?

>> 2. Are Korean knife sharpeners suitable for professional chefs?

>> 3. Can Korean knife sharpeners handle ceramic knives?

>> 4. How should I maintain my Korean knife sharpener?

>> 5. Where can I buy authentic Korean knife sharpeners internationally?

Korea has emerged as a significant player in the global knife sharpener industry, blending traditional craftsmanship with modern technology to produce high-quality sharpening tools. This article explores the top knife sharpener manufacturers in Korea, highlighting their unique offerings, manufacturing capabilities, and what sets them apart in the competitive market. We will also delve into the cultural and technological aspects behind Korean knife sharpening, providing a comprehensive guide for enthusiasts, professionals, and consumers alike.

Korea's rich history of metalwork and blacksmithing has naturally extended into the kitchenware and sharpening tool sectors. The country is home to manufacturers who combine centuries-old forging techniques with state-of-the-art production lines to create sharpeners that cater to both professional chefs and home cooks. Korean sharpeners are known for their durability, precision, and ergonomic designs, making them highly sought after in domestic and international markets.

The Korean kitchen culture places a strong emphasis on food preparation, which requires sharp, reliable knives. As a result, the demand for efficient and user-friendly knife sharpeners has grown steadily. This has encouraged manufacturers to innovate while respecting traditional methods, resulting in sharpeners that balance performance and heritage.

INSIGHT is a major force in Korea's kitchen knife and sharpener manufacturing industry. With a factory spanning 8,000 square meters and a monthly production capacity of 5 million knives, they also produce a variety of sharpening tools. INSIGHT integrates advanced heat treatment and precision grinding techniques to ensure consistent quality. Their sharpeners are designed to meet international standards, combining durability with ergonomic features to suit diverse culinary needs.

- Key Features:

- OEM/ODM services for global markets

- Advanced research and development for blade and sharpener innovation

- Corrosion-resistant materials for long-lasting performance

INSIGHT's sharpeners often feature multi-stage abrasive surfaces, allowing users to progress from coarse grinding to fine honing seamlessly. This versatility makes them popular among both professional chefs and home users.

Master Shin is renowned for traditional hand-forged knives and sharpening tools. Operating since 1845, this blacksmith shop is led by the 5th generation, Master Shin In-young, recognized as an Intangible Cultural Heritage Treasure. Their sharpeners often accompany their knives, crafted with traditional carbon steel and natural wood handles.

- Key Features:

- Handcrafted sharpeners with traditional techniques

- Use of natural materials for ergonomic comfort

- High sharpness and durability, reflecting Korean heritage craftsmanship

Master Shin's sharpeners are prized for their unique textures and ability to refine blade edges with a gentle yet effective touch, making them ideal for delicate culinary tasks.

Everwealth specializes in large-scale production of kitchen knives and sharpeners, operating over 15 production lines in a 5,000 square meter facility. They produce around 2 million knives monthly and offer sharpening tools with ergonomic handles and sharp edges optimized for professional use.

- Key Features:

- Automated polishing and robotic assembly lines

- Custom packaging and branding solutions

- Focus on sharpness, corrosion resistance, and user comfort

Everwealth's sharpeners often incorporate tungsten carbide rods and diamond-coated surfaces, ensuring rapid edge restoration and long-lasting sharpness.

LeeKnives offers a broad range of knives and sharpeners, including handmade and customized products. With over 30 years of experience, they blend modern CNC machining with traditional hand-finishing. Their sharpeners are designed to maintain edge retention and hardness, suitable for various knife styles.

- Key Features:

- Customizable sharpeners for branding and design

- Advanced heat treatment for durability

- Suitable for Western, Japanese, and Korean knife styles

LeeKnives also provides sharpening systems that allow users to adjust the sharpening angle, catering to different blade geometries and sharpening preferences.

Holy Industries is known for producing customized kitchen knives and sharpeners with strict quality control. Their sharpeners emphasize ergonomic design and corrosion resistance, crafted from premium stainless steel alloys with advanced heat treatment.

- Key Features:

- Tailored sharpening solutions for professional kitchens

- High-quality materials and craftsmanship

- OEM services for unique knife and sharpener lines

Holy Industries' sharpeners often feature multi-stage abrasive wheels and non-slip bases, making them user-friendly and safe for both commercial and home environments.

Korean sharpeners often feature a blend of traditional and modern elements:

- Material Quality: Use of high-grade carbon steel, tungsten, and diamond-coated surfaces for effective sharpening.

- Ergonomic Design: Handles and grips designed for comfort during prolonged use.

- Versatility: Suitable for various blade types including chef's knives, pocket knives, and specialized blades.

- Durability: Resistance to corrosion and wear, ensuring long-lasting performance.

- Cultural Craftsmanship: Some manufacturers incorporate traditional forging and handle-making techniques, adding cultural value.

The balance between manual craftsmanship and mechanized precision allows Korean sharpeners to appeal to a broad audience, from culinary professionals to everyday users.

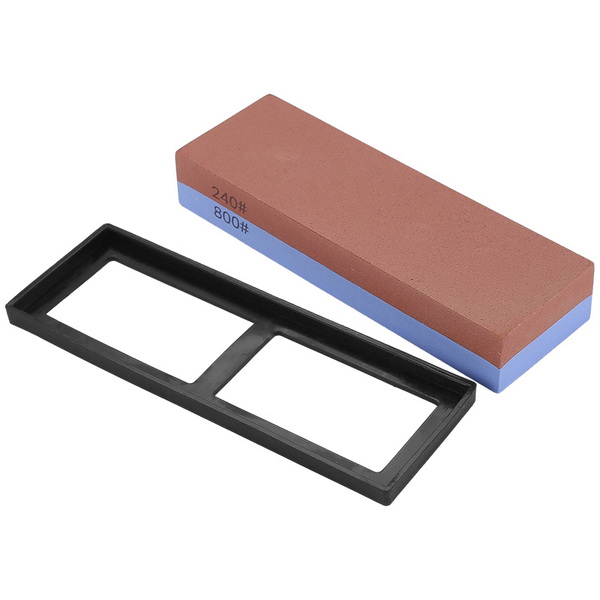

Most Korean sharpeners utilize a combination of abrasive materials such as diamond-coated wheels, ceramic stones, and tungsten carbide rods. These materials efficiently remove metal from the blade edge, restoring sharpness while maintaining blade integrity.

- Diamond Stones: Provide fast and effective sharpening for hard steels.

- Ceramic Stones: Used for fine polishing and honing.

- Tungsten Carbide Rods: Ideal for quick edge realignment.

Manufacturers often design sharpeners with adjustable angles to accommodate different blade geometries, ensuring precision and ease of use. Some sharpeners also include angle guides or magnetic holders to help maintain consistent sharpening angles, which is crucial for achieving a sharp and durable edge.

Korean manufacturers are embracing technology to enhance sharpening effectiveness:

- Magnetic Angle Guides: Help maintain consistent sharpening angles.

- Suction Cup Bases: Provide stability during sharpening without hand fatigue.

- Multi-Stage Sharpening Systems: Combine coarse grinding and fine honing in one device.

- Ergonomic Handles: Designed for both left- and right-handed users.

Additionally, some manufacturers have incorporated diamond-coated sharpening rods and ceramic stones into compact, portable sharpening kits, making it easier for users to maintain their knives on the go. These innovations improve sharpening accuracy and user experience, making Korean sharpeners competitive internationally.

Despite the rise of industrial manufacturing, many Korean knife sharpener makers continue to honor traditional methods. Hand-forged sharpening stones, natural whetstones, and wooden handles crafted from native hardwoods are still popular among artisans and consumers who appreciate authenticity.

Traditional sharpening techniques emphasize patience and skill, often requiring users to master specific angles and strokes to achieve the perfect edge. This cultural heritage is a key selling point for many Korean manufacturers who market their sharpeners as not just tools, but pieces of art and history.

Selecting the ideal sharpener depends on several factors:

- Type of Knife: Different knives require different sharpening angles and abrasives.

- User Skill Level: Beginners may prefer guided sharpeners with angle control, while experts might opt for traditional whetstones.

- Frequency of Use: Professional kitchens demand durable, fast sharpeners, while home cooks may prioritize ease of use.

- Portability: Compact sharpeners are ideal for travel or outdoor use.

- Budget: Prices vary widely depending on materials, craftsmanship, and brand reputation.

Korean manufacturers offer a wide range of sharpeners to fit these diverse needs, from affordable manual sharpeners to premium handcrafted stones.

Proper maintenance ensures the longevity and effectiveness of your sharpener:

- Clean Abrasive Surfaces: After use, rinse sharpening stones or rods with water and dry thoroughly.

- Avoid Harsh Chemicals: Use mild soap if necessary, but avoid abrasive cleaners that can damage surfaces.

- Store Properly: Keep sharpeners in dry environments to prevent rust or corrosion.

- Regular Inspection: Check for wear or damage and replace parts if needed to maintain optimal performance.

Following these simple steps will help your Korean knife sharpener deliver consistent results for years.

Korea's knife sharpener manufacturers represent a dynamic blend of tradition and innovation. From Master Shin's handcrafted sharpeners reflecting centuries-old techniques to large-scale producers like INSIGHT and Everwealth employing cutting-edge technology, Korean sharpeners offer quality, durability, and cultural authenticity. Their products cater to a wide range of users, from professional chefs to home cooks, ensuring sharp, reliable blades for every kitchen task. As Korean knife sharpeners continue to evolve, they are poised to gain even greater recognition in the global market.

Korean knife sharpeners often combine traditional forging techniques with modern materials like diamond and tungsten carbide, offering a unique balance of cultural craftsmanship and technological innovation. They emphasize ergonomic design and versatility for various blade types, distinguishing them from purely Japanese or Western styles.

Yes, many Korean sharpeners are designed for professional use, featuring durable abrasive materials, ergonomic handles, and precision angle guides that maintain sharp edges even under heavy daily use.

Most Korean sharpeners focus on steel blades and may not be suitable for ceramic knives, which require specialized sharpening tools due to their hardness and brittleness.

Regular cleaning of abrasive surfaces with water or appropriate cleaning tools is recommended. Some sharpeners do not require water during use, while others benefit from slight moistening for a mirror finish. Always follow the manufacturer's guidelines.

Authentic Korean knife sharpeners are available through specialized kitchenware retailers, online marketplaces, and directly from manufacturers offering OEM/ODM services. Many brands have international distribution channels catering to global customers.